Simplifying Material Loss Tracking and Recovery for Jewellery Manufacturers

Simplifying Material Loss Tracking and Recovery for Jewellery Manufacturers

Jewellery Manufacturing

India

NetSuite Customization

Client Portfolio

Our client is one of India’s leading diamond jewellery manufacturers and exporters. Renowned for their exquisite, high-end diamond-studded gold jewelry, the company has built a reputation for creating versatile designs that celebrate individuality and illuminate life’s special moments. With multiple manufacturing units and a legacy rooted in artisanal excellence, their operations blend traditional craftsmanship with modern innovation.

Despite their design innovation and market leadership, they faced a critical challenge on the operational side: controlling and tracing material loss during the production lifecycle

Problem Statement

One crucial and recurring issue that the jewellery manufacturing industry faces is the untraceable loss of raw materials during each stage of production. In jewellery manufacturing, even a 0.1% material loss can lead to a significant financial impact.

While the artisans excelled at craftsmanship, the backend processes lacked the structure needed to monitor the metal usage and loss accurately. Our client relied on manual logs, spreadsheets, and verbal tracking methods to monitor raw materials, including gold, alloy, and precious stones, consumption and wastage across their production units.

The client’s key pain points included:

· No real-time tracking of material usage across production stages

· Inability to exactly pinpoint where, at which stage, how, how much, and by whom the material loss occurred

· Lack of traceability from raw material issue to finished product

· Difficulty in accurately tracking by-product recovery after each stage

· Lack of a systematic costing approach with a first-in-first-out costing method for each item

· Manual reconciliation delays affecting profitability and audits

What We Suggested

After a rigorous analysis, our expert team developed a solution aligned with the standards and intricacies of the jewellery manufacturing industry. We introduced Jewellery Manufacturing Suite, built on Oracle NetSuite, with a focus specifically on loss tracking and reports with operational visibility.

Built specifically for goldsmiths, jewellery manufacturers, and production houses, the Jewellery Manufacturing Suite helps:

· Track gold, alloys, and gemstones across all stages, capturing attributes such as purity, batch, shape, weight, and piece across every location — from melting to setting

· Real-time order and production status tracking, allowing visibility from the time of material issue to job completion

· FIFO-based costing for accurate profitability and valuation of every item, especially useful in bulk production and fast-moving collections

· Monitor raw material flow from procurement to production to final product

· Track raw material in each bag during every production stage, giving clarity on material consumption at each process stage, including casting, plating, filing, polishing, setting, and finishing

· Job bag linked to specific material consumption records to monitor material depletion

· Log wastage, scrap, and recoverable gold losses down to every single gram in the production stages

· Automatically generate reconciliation reports to help compare expected loss vs. actual loss and detect variances immediately

· Barcode and serial number tracking to ensure every finished good is auditable and traceable from the vault to the customer

This was vital to their operations and enabled the company to not only track but also control material losses through better planning, training, and oversight.

Customer Success

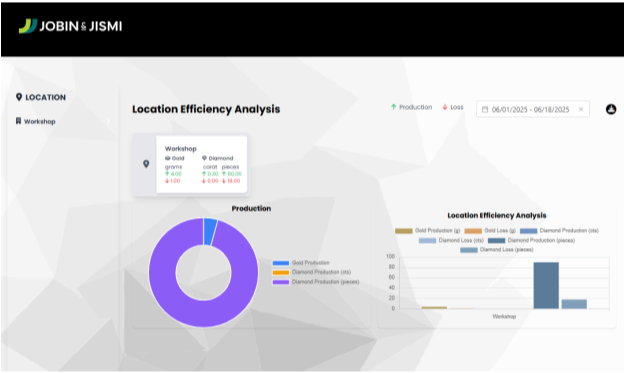

The implementation of our Jewellery Manufacturing Suite enabled the client to proactively address one of the most pressing pain points in the jewelry manufacturing industry: material loss tracking during production. Prior to this, the client struggled with fragmented data, manual logs, and limited

visibility into raw material consumption and recovery. With our jewellery ERP, they shifted from reactive reconciliation to real-time, stage-wise monitoring of gold, diamond, and stone usage across bag movement in the production cycle.

By unifying the Bill of Materials (BOM), Job Card tracking, and recovery insights within NetSuite, the client gained unprecedented transparency and control over every gram of precious material. This transformation significantly improved operational confidence during audits and minimized financial leakage.

Key Achievements

· Reduced material loss through precise loss identification and control.

· Minimized reconciliation time, accelerating closing cycles.

· Achieved full traceability of gold, diamonds, and stones throughout the manufacturing lifecycle.

· Ability to track by-product recovery such as polishing dust and scrap recovery, which are vital to protect margins in operations.

· Identified the top loss-contributing stages, enabling targeted corrective actions.

· Strengthened compliance and audit preparedness with system-based reconciliation reports.

Way Forward

The successful deployment of our Jewellery Manufacturing Suite has helped the client gain real-time insights and better control over the high-value materials. With their material loss-tracking now streamlined, the client can explore further automation in inventory forecasting and predictive analytics for loss prevention. Further enhancements could include machine learning models to detect anomalies in material usage patterns and real-time alerts for deviations, leveraging NetSuite’s robust infrastructure and Jobin & Jismi’s domain expertise.

Ready to transform your jewellery manufacturing operations? Our team of NetSuite experts, backed by deep domain knowledge in the jewelry industry, is here to help you overcome your operational challenges with our jewellery manufacturing ERP.

Connect with us today to discover how our Jewellery Manufacturing Suite can help you streamline your manufacturing processes and unlock new levels of efficiency and profitability.